First, we need to determine whether the pipette is leaking.

1. Detection method:

1) Visual inspection: first use the pipette to be tested to absorb the liquid, and then let it stand vertically for 15 seconds to observe if there is any droplet flowing out slowly. If droplets flow out slowly, it means that the pipette is leaking.

2) Pressure pump detection: Use a dedicated pressure pump to detect the pressure and determine whether the pipette is leaking.

2. If there is a leak in the pipette, then we must analyze the possible causes of the leak:

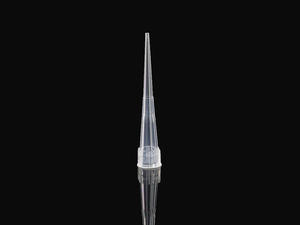

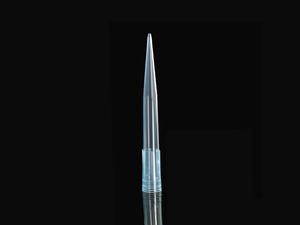

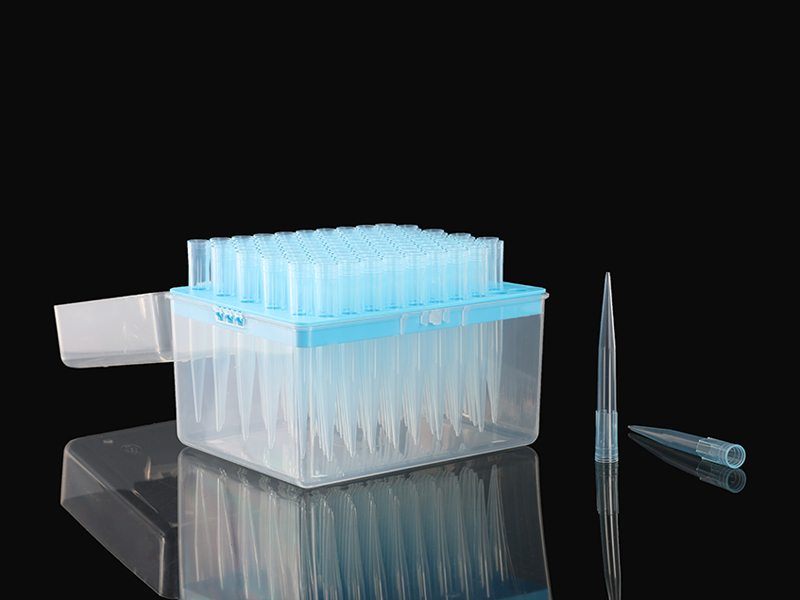

First, check if the tip matches? It is recommended to use the original matching tip. If it is not the original matching tip, it is best to consult the manufacturer or agent to see if the tip you are using matches the pipette you are using.

Secondly, is it tightened when assembling the tip? It is possible that the pipette leaks due to not tightening the tip when installing it.

Finally, if no problems are found in the above two cases, it is likely that the internal air tightness of the pipette is not good. At this time, you need to contact the pipette company maintenance engineer.

After we have ruled out the first situation above, we have to investigate the second situation:

We need to detect whether the temperature of the pipetting liquid and the temperature difference between the pipette and the pipette tip have affected the accuracy of the pipette.

Under normal circumstances, when the temperature of the pipetting liquid is inconsistent with the temperature of the tip and pipette, the following two differences will occur:

1. When the liquid temperature is higher than the tip, the volume of liquid to be pipetted will be too large;

2. When the liquid temperature is lower than the tip, the volume of liquid to be pipetted will be too small

If the second case is still ruled out, then we have to investigate the following third case:

Observe whether there is a significant difference between the density of the liquid sample and the water?

Generally speaking, the calibration of the pipette before leaving the factory is tested with water as the standard liquid. Therefore, if the specific gravity of the liquid being operated is very different from that of water, the accuracy and accuracy given may not be satisfied. An error occurred.

After all the above problems are eliminated, we should also pay attention to the aspiration speed not to be too fast. Too fast aspiration speed will cause backwash and bubbles, which will lead to inaccurate pipetting volume, which will eventually affect the accuracy of the pipette.

简体中文

简体中文