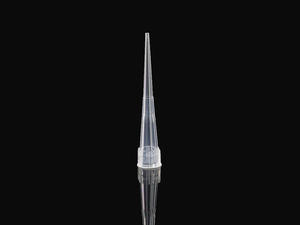

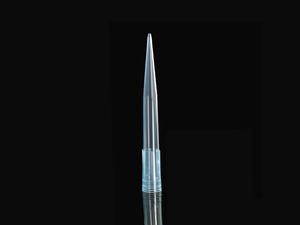

Appearance verification:

Observe with visual inspection, manual or reading magnifier, which should meet the requirements of appearance

Test of tightness:

1. Use a transparent wide-mouth reagent bottle filled with clean water, with three holes in the stopper, and install the vacuum gauge, test glass tube, and suction device (optional Sichuan glass syringe) on the stopper.

2. Connect the pipette to be tested to the upper end of the test glass tube that invades the liquid 5cm, and start the suction device. Make the pointer of the vacuum gauge at (0.04MPa, 5s after reaching equilibrium, at this time There must be no air bubbles at the lower end of the test glass tube.

Inspection requirements are divided into three levels by department

First level: Pipettes with precision use as the main department must fully meet the calibration standards

Level 2: Used by departments with secondary precision requirements, mainly used in departments that do not require full accuracy

Level 3: Pipette use only needs to get approximate doses

Level 4: This level is the level of pipette abandonment

Verification of pipettes by means of measurement.

Preparation before the test

The nozzle used should match the suction rod of the pipette being tested. At the lower end of the suction rod of the pipette, gently turn the nozzle to ensure the tightness of the pipette, and there should be no water hanging during the process of aspiration and drainage.

Single-hole detection of multi-head pipettes

简体中文

简体中文